• VibroBLAST Technology (Wet) VBA WET

The Wet version of the VibroBLAST technology reveals fundamental differences with the “classic” wet-blasting or vapour blasting known on the market.

Infact the “kinetic energy” used in a classic wet-blasting cabinet is using compressed air (venturi mode) combined with “slurry” (a mix of water and blasting media), which is generally helped to reach the blasting nozzle by means of a special anti-abrasive pump.

The VibroBLAST wet technology can use this classic way of blasting, where needed.

Nevertheless, in other occasions, can use compressed air combined with a pump of special abrasive gel which main advantage is to be used just one time.

The reason of this is to avoid pollution of the workpieces surface – in some applications like medical, food and beverage, aerospace, and similar fields.

As alternative to compressed air, in some circumstances where also a very delicate or “soft-blasting! Is required, instead of compressed air as a vector, it is possible to use Saturated Dry Steam at a pressure between 8 and 10 Bar.

The combination with special abd elastic “QF! Media, allos finally also to dry the components, at the end of the process, using hot air blowers.

All this, of course, is available exclusively in terms of taylor made systems that, depending on every single specific application, may differ one from the other.

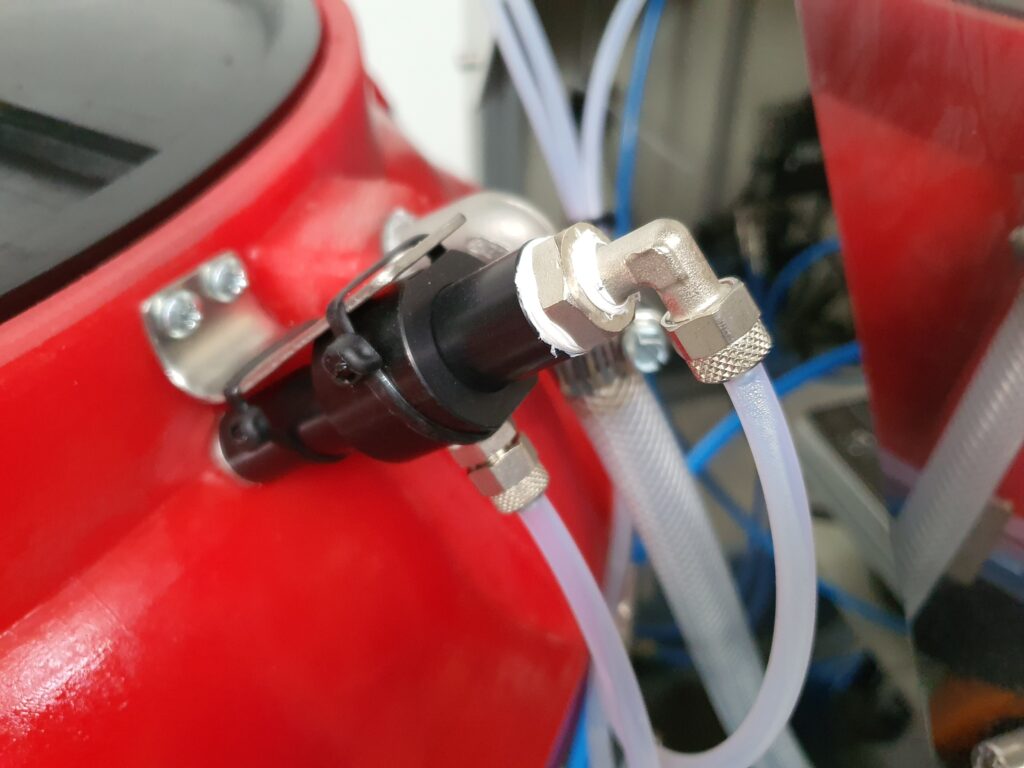

A Steam Blasting Nozzle applied to a working bowl of 50 liters capacity unit.

Feel free to get in touch with: info@integram.eu