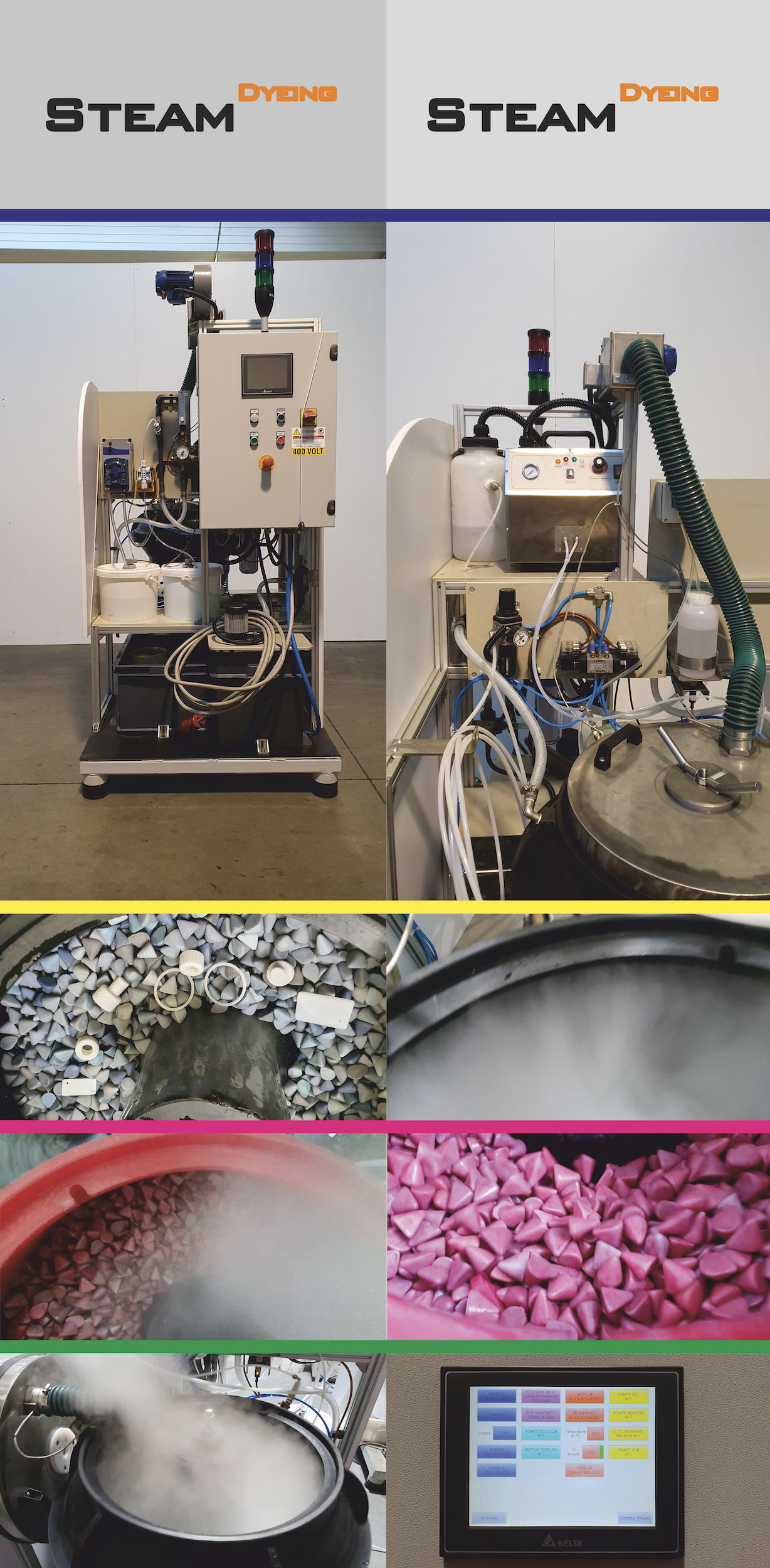

• STEAM DYEING TECHNOLOGY

The “steam dyeing” technology, a patent pending solution registered by Techno Surface, is operating with drastically reduced use of colours and, as well, significant reduction of the final produced waste.

Extremely low carbon footprint combined with high efficient automation based on recipes, assuring repeatable quality, deep and homogeneous dyeing, top quality results.

When you need to get homogeneous and deep colours on your plastic or composite components, using 10 to 20 times less colours than with conventional dyeing processes, with automatic tasks based on recipes, the Steam dyeing technology is the right approach, assuring a fast Return of Investment.

The main actors of this NETWORK in more details:

Techno Surface is an Italian company founded in 2015 and specialized in various technologies, with strong convergence towards Additive Manufacturing. Engaged since its inception in technological consultancy and R&D, it has filed a series of specific patents for post-process applications and surface treatments in AM. These innovations include the Eco-Sonic 3D ultrasonic cleaning system, the eco-friendly Steam-Dyeing of polymers. Techno Surface is the coordinator of the IntegrAM program and network.

Rollwasch® is an Italian company founded in 1950 in Milan and specialized in surface treatment. Manufacturer of machines and consumer products, Rollwasch® is an innovative SME, always engaged in R&D, which in the last decade has developed a series of patents to revolutionize post-processing and finishing in AM. In 2021 Rollwasch® won the first prize in the Innovation 4.0 Award, as part of the 15th edition of the A&T – Automation & Testing Fair, with VibroBLAST technology.

DCL (Dyeing Colour Lab) is the competent reference point selected by the companies part of the IntegrAM network, to supervise and manage the innovative program of pigments and colours involved in the Steam Dyeing technology.

Rollwasch® has, inside its own organization, a very expert chemical manufacturing unit where the DCL Lab is just a specific area of its labs, destinated to support all the products related to the Dyeing technology, for the full network of companies part of IntegrAM.