SURFACE PREPARATION is the correct term to better identify (not only in the AM field) that kind of surface treatment process which target is to “prepare” the surface for a following step. Unlike a “surface finishing” process, which is intended to be a further kind of surface treatment process with the main target is to “finish” the surface in the finest possible way (like very fine roughness, glossy or mat outlook, and so on).

One typical surface preparation process is the classic sand blasting, by hand or with rotary barrell blasting piece over piece.

An alternative and innovative surface preparation process is the VibroBLAST technology, a patent pending innovation, where special elastic media are protecting (like small airbags) the workpieces during the sand blasting operation, making possible to avoid the use of hands also in case of delicate components. The limits of this technology is to apply on medium small size parts, not to very big size parts – another limit are parts that during the 3D printing process occupy the whole build and remain full of powder inside (example, the body of a lighting element for a car, with a small orifice to empty the powder contained – that is generally handled by hand or with a robot).

What about The VibroBLAST technology?

• The VibroBLAST technology is available in several operative modes, depending on the surface preparation needs.

Lets see those different variants, as follows:

• VibroBLAST Technology (Dry) VBA DP

DP stand for “De-pressure” or “Venturi” blasting technology – with this technology it is possible to use every kind of blasting media except the metallic ones;

Accordingly it would be possible to use glass beads, ceramic beads, melamine granulates, aluminum oxide, and similar / well known blasting media;

Feel free to get in touch with: info@integram.eu

• VibroBLAST Technology (Wet) VBA WET

The Wet version of the VibroBLAST technology reveals fundamental differences with the “classic” wet-blasting or vapour blasting known on the market.

Infact the “kinetic energy” used in a classic wet-blasting cabinet is using compressed air (venturi mode) combined with “slurry” (a mix of water and blasting media), which is generally helped to reach the blasting nozzle by means of a special anti-abrasive pump.

The VibroBLAST wet technology can use this classic way of blasting, where needed.

Nevertheless, in other occasions, can use compressed air combined with a pump of special abrasive gel which main advantage is to be used just one time.

The reason of this is to avoid pollution of the workpieces surface – in some applications like medical, food and beverage, aerospace, and similar fields.

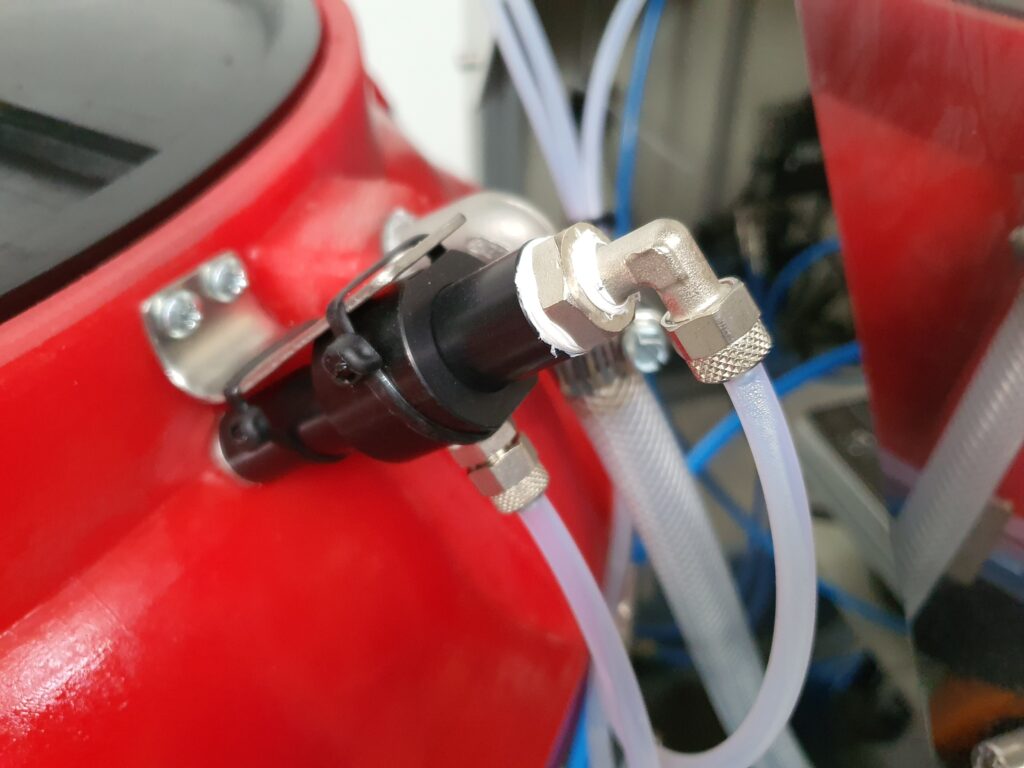

As alternative to compressed air, in some circumstances where also a very delicate or “soft-blasting! Is required, instead of compressed air as a vector, it is possible to use Saturated Dry Steam at a pressure between 8 and 10 Bar.

The combination with special abd elastic “QF! Media, allos finally also to dry the components, at the end of the process, using hot air blowers.

All this, of course, is available exclusively in terms of taylor made systems that, depending on every single specific application, may differ one from the other.

A Steam Blasting Nozzle applied to a working bowl of 50 liters capacity unit.

Feel free to get in touch with: info@integram.eu

• VibroBLAST Technology (Pressure) VBA-PR

PR stand for “Pressure” blasting technology – with this technology it is possible to use every kind of blasting media included the metallic ones;

Accordingly it is possible to use not only glass beads, ceramic beads, melamine granulates, aluminum oxide, and similar blasting media, but ALSO STEEL, STAINLESS STEEL and other kinds of alloys of METALLIC MEDIA;

The PR range of VibroBLAST equipments is extremely competitive, compared with the classic pressure-blasting cabinets, but much more when compared to rotery belt type turbine blasting equipments.

One of the limits of the Pressure VibroBLAST equipments is the minimum size, sterting from the minimum circular bowl size of 300 liter with pneumatic cover, pneumatic discharging port and other interesting automatic features.

Feel free to get in touch with: info@integram.eu

or, even visit our website www.rw-blasting.com