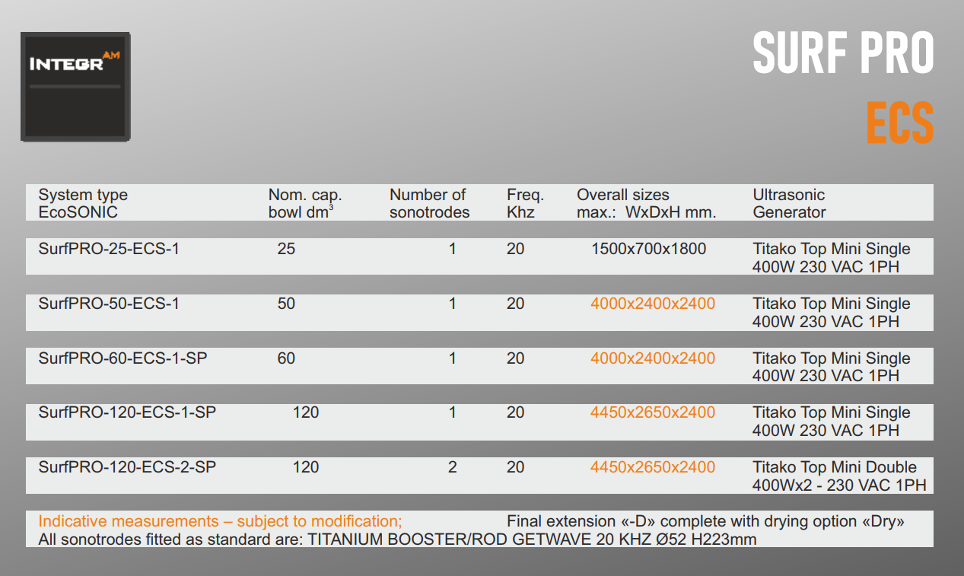

This allows to manage alternative, more complex and complete processes than just washing and rinsing, including, where required, the ultrasonic cavitation action, with obvious advantages in surface treatment strategies.

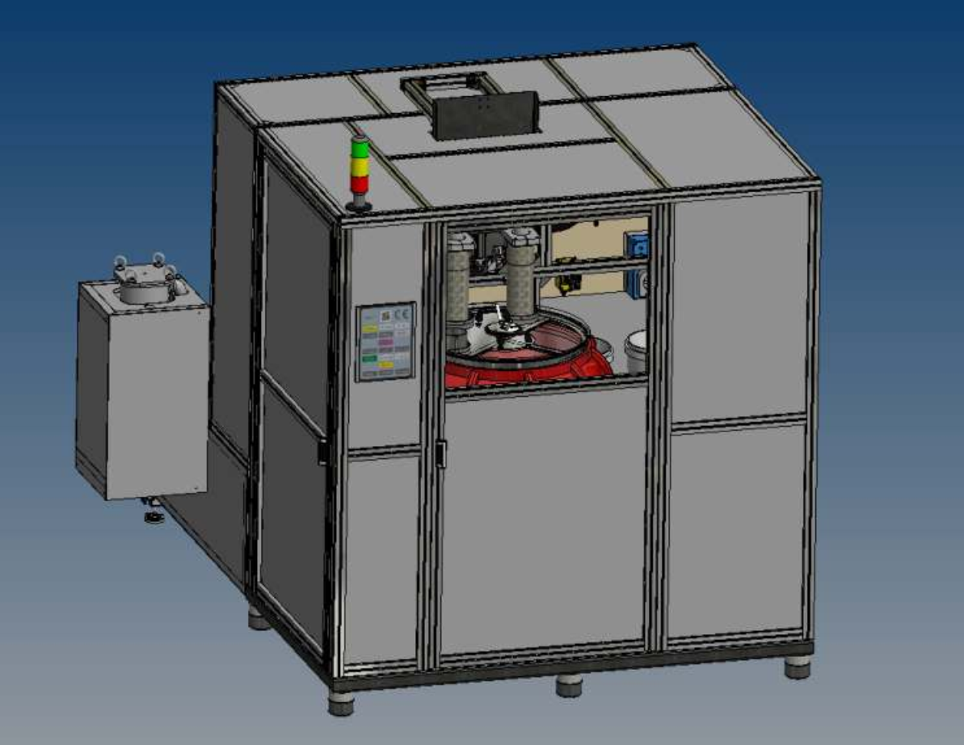

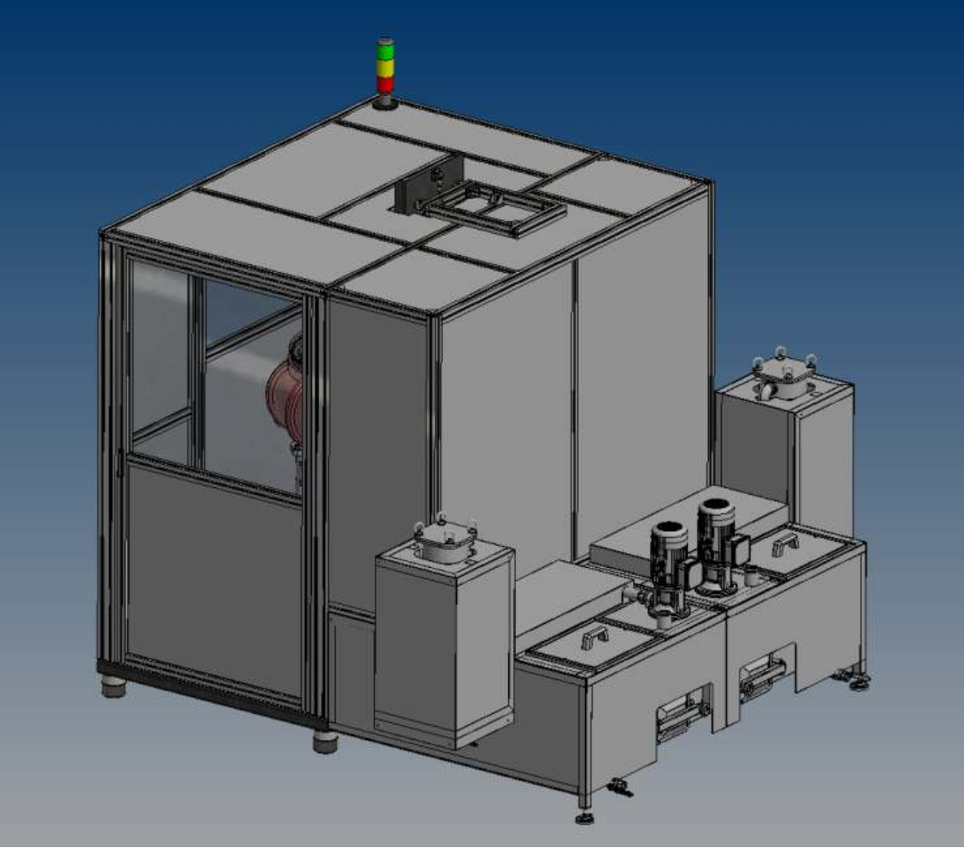

Front view of the SurfPRO-120-ECS-2-SP

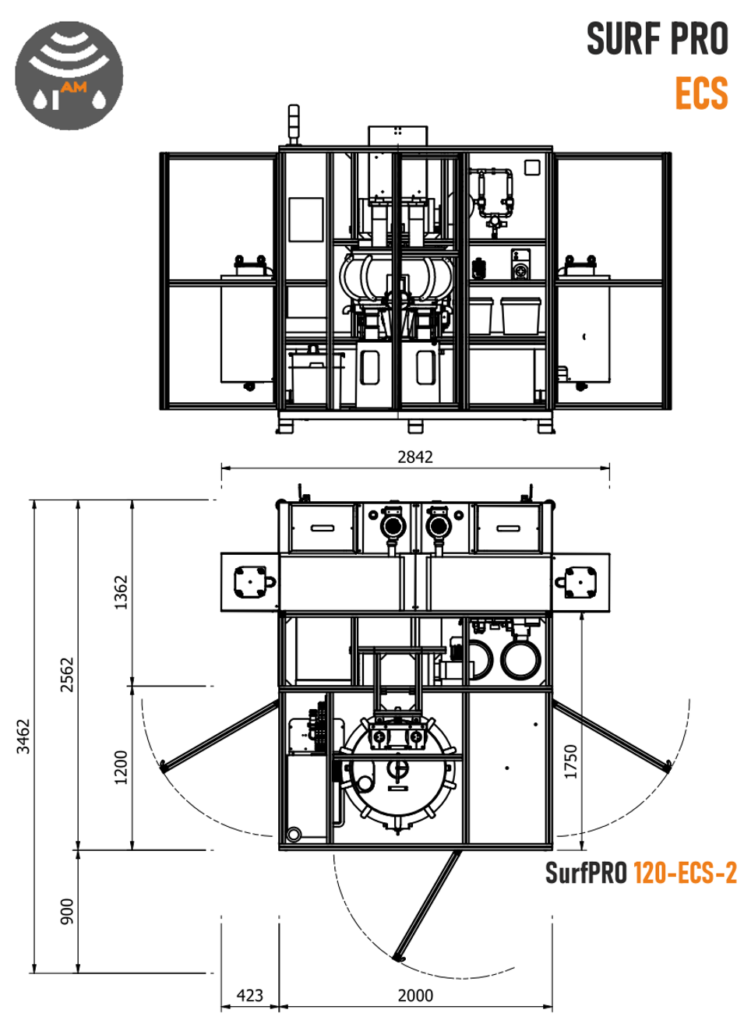

Rear view of the system, where the washing and rinsing stainless steel tanks are positioned – the design is based on symmetric and mirror tanks, complete with filters and pumps.

Between other advantages, the compressed space required to offer so many possible automatic tasks in sequence, makes this system a true MILESTONE in the ultrasonic washing technology.

All machines are available with HMI designed with a touch screen colour display combined with software to manage recipes of different kinds, tailor made for each customer.

Once checked-out at our premises, before shipment, our system can be easily positioned and started up based on the PLUG & PLAY concept of the pre-assembled systems.

For further information : tech@integram.eu

XPERT

Spencer Williams

integram.team@gmail.com

CATEGORIES

Technology:

Post Process & Finishing for AM, Dyeing, Powder recovery & selection, Surface Finishing, Unpacking or Decaking, Coating

Specific category:

Post Process & Finishing for AM; Scientific Head of R&D; Webinars & Seminars; Circular Economy Technology;

COMPANY

IntegrAM

www.integram.eu