(DePressurized/Venturi mode)

The Rollwasch® program for dry sandblasting combined with vibratory finishing machines offers new horizons to your expectations. The standard program SUPER-VibroBLAST-Air DP (Patent pending – I) consists of models available both with depressurized or Venturi mode (DP) and direct pressure (PR) technology.

In this editorial, we just talk about DP models, recently presented in WORLD PREMIERE at Mecspe exhibition, in Bologna, from 6 to 8 March 2024.

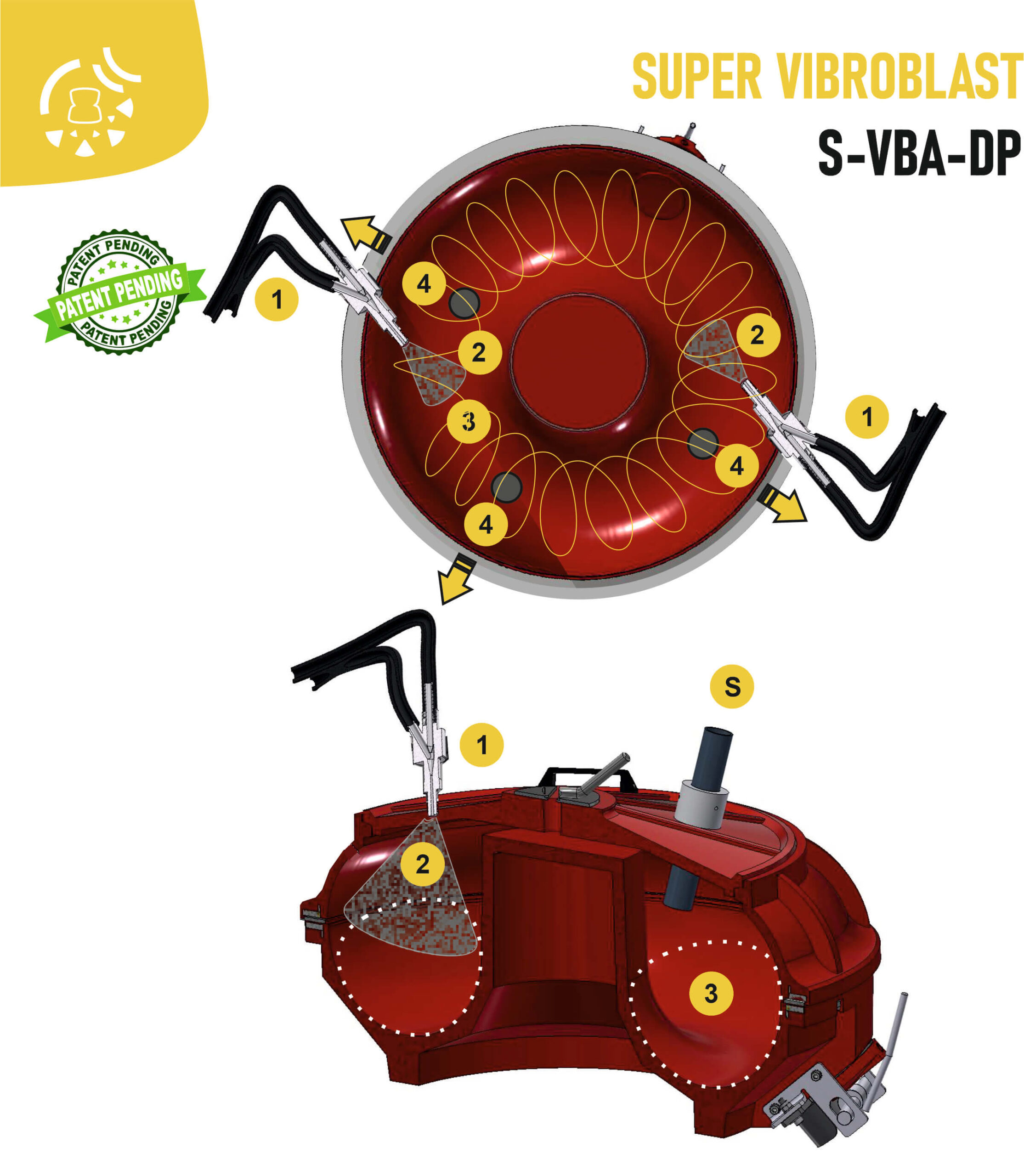

The range of machines starts with nominal capacities of 60 and arrives up to 120 litres with blasting nozzles involving in 3D the mass-loaded parts in the vibratory finishing unit, thanks to special elastic mewdia QF (Patent pending). The SUPER-VibroBLAST-Air DP model 120 has TWO (2) BLASTING NOZZLES and three (3) exhaust filter in the working bowl, whilst the model 60 has ONE (1) BLASTING NOZZLE and also three (3) filters.

AS: Antistatic system for polymers – a useful option when processing components in PA11, PA12, TPU, or Composites;

HANDS-FREE!

With VibroBLAST you do not use your hands to sand one piece at a time! Sandblasting takes place in mass and in 3D inside a vibratory finishing machine (Patent pending I).

The SUPER-VibroBLAST-Air DP system presented in world premiere has TN (Top Nozzles) sandblasting nozzles placed in the cover upper area, to involve from above the treated components, while they rotate three-dimensionally, clockwise, inside the circular vibro-blasting tank.

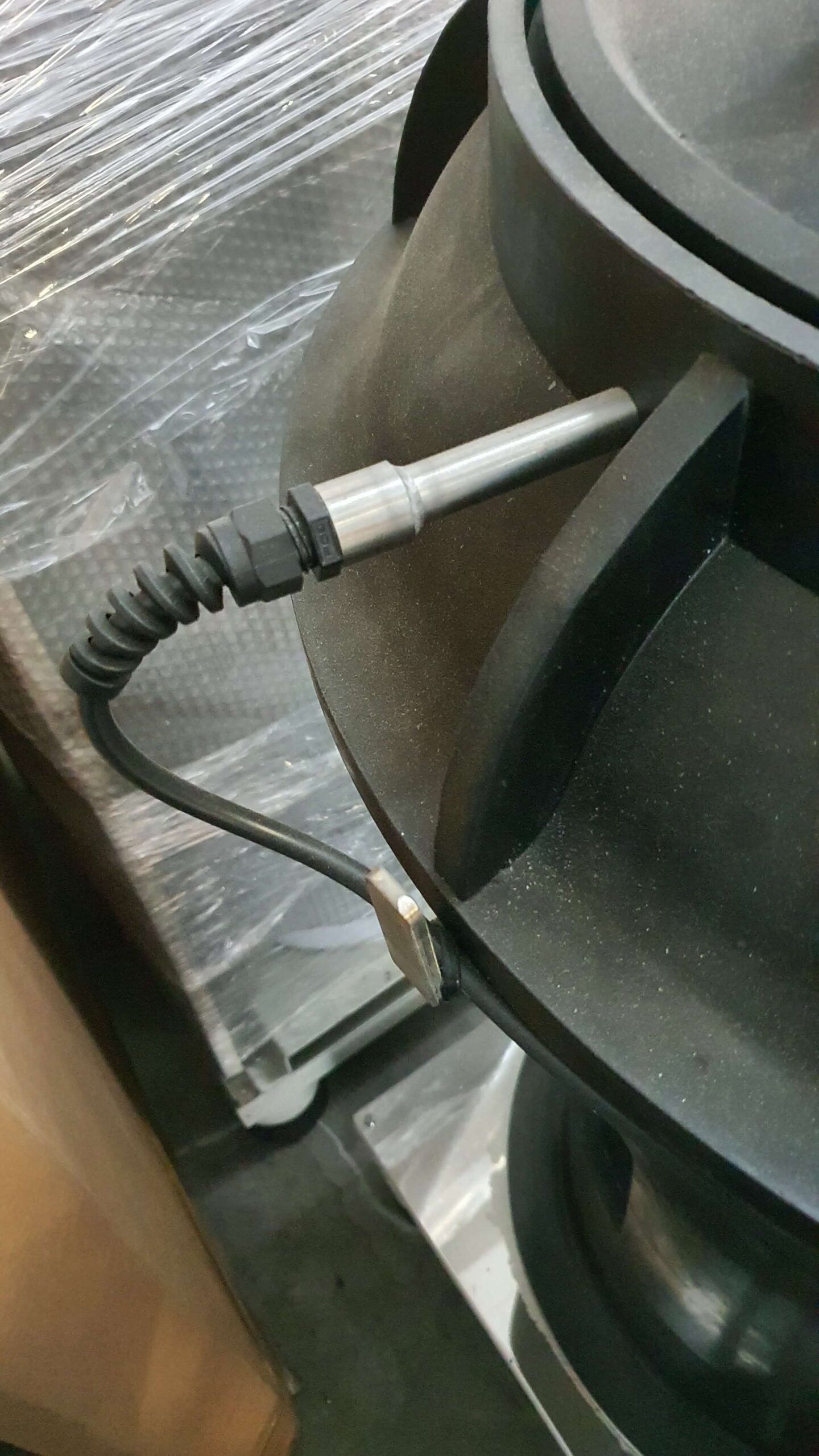

At the apex of the cover, we therefore have the nozzle [1] with vertical adjustment [2], placed above the mass being processed [3]. The cover S-VBAincludes 3 snorkles [S], two ove the cover and one “external”.

The presence of 3 discharge filters [4], instead of the single filter in the basic version, allows the Super VibroBLAST to carry out treatments with pressures of up to 6 bar with the certainty of a total and effective discharge of the sandblasting media.

At the same time, the components subjected to vibro-sandblasting meet the nozzles every 180°, instead of every 360° as in the basic version.

PLUG&PLAY DESIGN

The SUPER-VibroBLAST-Air DP line is designed and manufactured to be supplied on a technological pallet, to make its installation immediate through a simple plug-&-play operation.

It is enough to connect air (DRY AIR, up to 6 Bar) and the Euro socket to the designated Power line and the machine can start working as it was programmed during the try-out phase before shipment.

We take particular care of manufacturing quality, safety and ergonomics.

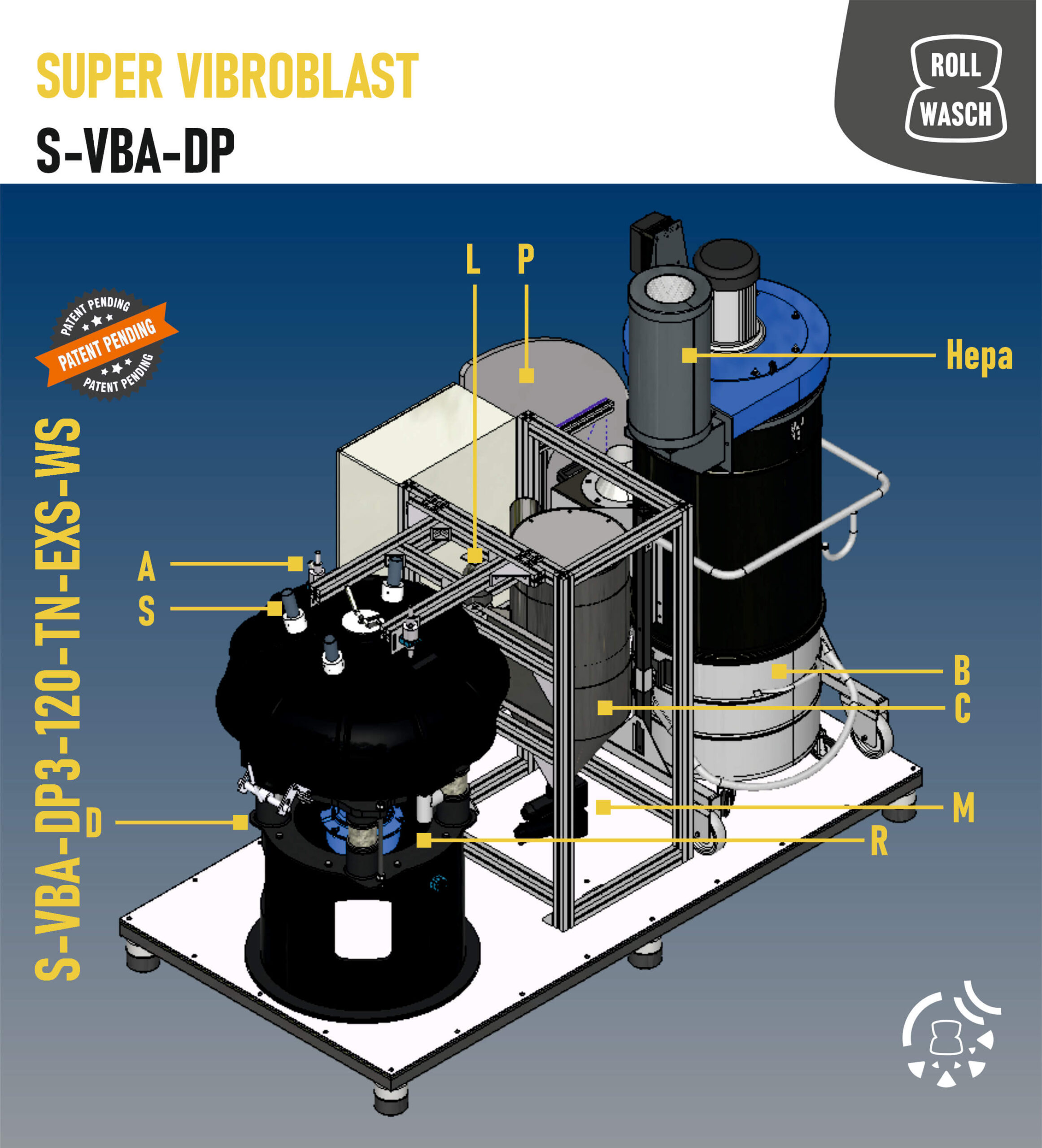

All SUPER-VibroBLAST-Air DP systems starting from 120 size are the result of careful design being characterized by: A) two sandblasting nozzles; S) three air inlet snorkels; B) filtered dust collection container – on the same side as C) cyclone loading door for sandblasting media; D) side for total discharge from the tank door; M) two air-sand mixing groups (see specifications on page 11); R) three connections for filtered sand discharge, in correspondence with the three filters on the tank bottom; L) InterLock – safety lock on shot nozzles support bars; P) protective panel; Hepa) the filter aspirator is equipped with a standard filter M (1 micron) and an outlet silencer.

The Super VibroBLAST Air DP system includes two tilting bars to support the two sandblasting nozzles. In this representation the bars are raised, an operation performed manually by the operator only at the end of the work cycle – in this case the safety interlock releases the constraint to be able to tip over the bars upwards. The operator will thus be able to open the access cover to the work tank and start it where required for loading and unloading operations, without the risk to activate the sandblasting nozzles – they are in fact inhibited by the interlock sensor.

Once the cover is closed and the bars are lowered with the interlock active, the sandblasting nozzles can be activated in complete safety – there are two protective bellows around the cover upper holes;

All Super VibroBLAST Air DP systems have been designed to ensure excellent aspiration and filtration, with ATEX Zone level 20 or 22 inside the aspiration unit.

To increase its performance, the basic machine is painted with a new type of glossy paint to minimize dust sticking to the internal walls. The air exhaust collector is equipped with a silencer. Super VibroBLAST systems can be equipped with the automatic filter cartidges shaking – all three exhaust collectors of relevant filters on the bottom of the tank are equipped with an air inlet in order to facilitate sandblasting powders and grains evacuation. It is always recommended to use de-humidified compressed air

All Super VibroBLAST Air DP systems have been designed to ensure, where required, a stainless-steel cyclone feeding the sandblasting media, as an alternative to that of painted carbon steel. This happens, for example, in sectors such as medical, food or all contexts in which this solution is necessary.

At the same time, with the standard cyclone in painted carbon steel, the (2) air-sand mixing groups mounted under the lower cone are made of aluminium.

In the version with stainless-steel cyclone, the two mixing groups are made of non-toxic and anti-abrasive polyurethane, with stainless-steel fittings and inserts.

All Super VibroBLAST Air DP systems have been designed to ensure, where required, a stainless-steel cyclone feeding the sandblasting media, as an alternative to that of painted carbon steel. This happens, for example, in sectors such as medical, food or all contexts in which this solution is necessary.

At the same time, with the standard cyclone in painted carbon steel, the (2) air-sand mixing groups mounted under the lower cone are made of aluminium.

In the version with stainless-steel cyclone, the two mixing groups are made of non-toxic and anti-abrasive polyurethane, with stainless-steel fittings and inserts.

SURFACE FINISHING FOR TARGET

SF4T is very happy to advertise a so INNOVATIVE solution, immediately after its WORLD PREMIERE in BOLOGNA, meeting the surface preparation in a dry mode (environmentally friendly, respect to wet alternatives polluting waters) – it is good to say that the VibroBLAST technology made from Rollwasch is BETTER FOR PLANET!

XPERT

MdM Paolo Redaelli

paolo.redaelli@rollwasch.it

CATEGORIES

Technology:

Blasting, Grinding, Media and consumables, Peening, Polishing, Post Process & Finishing for AM, PMRF, Safety, Health and Environment, Vibratory finishing

Specific category:

Vibro-blasting equipments, Vibro-Peening equipments

COMPANY

Rollwasch Italiana S.p.a.

www.Rollwasch.it