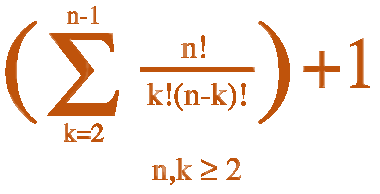

The innovative secret formula

The surface finishing in AM of metal parts, After de-powdering and surface preparation

After depowdering of metal components produced with DMLS, SLM, LPBF or similar process, it is a «must» to follow up with a suitable Surface Preparation and, immediately after, with an accurate Surface Finishing. VibroBLAST technology is normally the first step to follow for two reasons:

- The highest peaks of the rugosity are reduced, thus preparing the surface for its best following «accurate finishing» with a reduced time;

- Small «droplets» of hardened powder still remaining sticked to some points of the surfaces, are easily removed, leaving the geometry of the component as required by the original 3D drawing;

The surface finishing in AM of metal parts, Must first follow a suitable surface preparation

When metal components have high rugosity and sizes are of medium small size, it is the correct condition to prepare them using the innovative VibroBLAST Surface Preparation technology.

IntegrAM has designed and produced automatic VibroBLAST systems to save a big volume of time by launching automatic cycles based on recipes.

One example is given by the «case study» approached in cooperation with the digital platform SF4T – Surface Finishing For Target

The final result after MF finishing, is the best «start» for further precision steps

- After the final result of the MicroFLUID finishing process has assured constant results with:

- Extremely smooth surfaces

- Very reduced rugosity

- Homogeneous and repeatable results

It is possible to forecast the final precision machining of the areas where the needs of final manufacturing are very high levels, or further steps, such as ultrasonic washing, electrochemical cleaning, and so on.

Watch the video:

The final result after MF finishing, is the best «start» also for many more items!

MicroFLUID finishing process is able to assure interesting benchmark also in many other components, starting from small ones to very, very big. Precision parts up to over 2 meters external diameters have been succesfully processed with special Microfluid systems.

Let’s talk about it!

XPERT

Spencer Williams

integram.team@gmail.com

CATEGORIES

Technology:

Post Process & Finishing for AM, Dyeing, Powder recovery & selection, Surface Finishing, Unpacking or Decaking, Coating

Specific category:

Post Process & Finishing for AM; Scientific Head of R&D; Webinars & Seminars; Circular Economy Technology;

COMPANY

IntegrAM

www.integram.eu