Company

ROLLWASCH ITALIANA SPA

Referent

PAOLO REDAELLI

C.E.O.

Title

BACKGROUND OF THE VIBROBLAST TECHNOLOGY 2007-2024

Interview by

LAURA DE CAPITANI

Editor of SF4T

Brief introduction of the VibroBLAST technology, by the Editor of SF4T: LAURA DE CAPITANI

Rollwasch Italiana S.p.a. during the year 2019 has presented as a WORLD PREMIERE its innovative hybrid technology VibroBLAST, showing its first system respectively in France, at 3D PRINT LYON and in Germany, at FORMNEXT. This technology is combining two different technologies, like vibratory finishing and blasting in a single system – suitable for medium small size parts in plastic or metal or composites. Thanks to a special kind of special elastic vibratory finishing media, called QF, the workpieces processed into a VibroBLAST system can be delicate parts and can be loaded in mass, solving main issues, like:

- Fully automated blasting process, without shocks and damages also for delicate components;

- Mass blasting of wide batches, i.e.: 100 parts per cycle, can be process at once, involving the operator time only a few minutes for loading and unloading;

- Thanks to a mix of innovative patents, the VibroBLAST technology is perfectly suitable not only for industrial components or Additive Manufacturing parts, but also perfect to blast medical components, parts related to the food industry etc.

Between 2019 and 2024, this technology has solved hundreds of projects, with a winning philosophy.

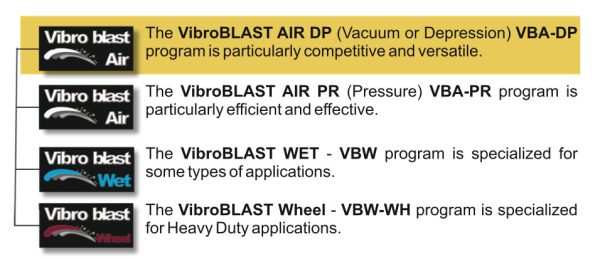

Thanks to a never-ending R&D activity, Rollwasch has developed several variants of the VibroBLAST technology, initially based on de-pressure (venturi) dry air mode, then extended to the pressure dry air mode, then today also applied to dry turbine shot blasting and with wet blasting.

The today’s interview is looking to the backgrounds of this “never-ending” R&D activity that Rollwasch started many years before its official presentation to the international markets!

Laura De Capitani/Editor:

Mr. Redaelli, Let’s start from the beginning, can you tell me what happened in the year 2007?

Mr. Paolo Redaelli, C.E.O. of Rollwasch Italiana S.p.a.

Everything started in 2007 at the Company Rollsystem Srl, in Nibionno (LC) – Italy, as part of the Rollwasch property, Company specialized for manufacturing abrasive media and chemical compounds. That was the «start» of the first secret R&D activity, to evaluate the feasibility of the project «Quattrofinish», also called «QF Media». QF Media, later on, have been validated and became the necessary «key» to perform dry finishing and dry surface preparation processes. Between others, one of the «outstanding» projects of all dry technologies: VibroBLAST – took a long amount of time to develop, the longest that Rollwasch has ever managed before.

Laura De Capitani/Editor:

When the “QF media” becomes a reality at Rollwasch?

Mr. Paolo Redaelli, C.E.O. of Rollwasch Italiana S.p.a.

In the new «QF-AREA» in the factory of Rollwasch Italiana Spa, in Albiate (MB) – Italy - Rollwasch has started a considerable investment plan, purchasing a couple of injection moulding units from Negri Bossi, Leading Italian manufacturer. A relevant part of the investment is also focused on the mould manufacturing of several kinds of shapes and sizes. In the top picture, Paolo Redaelli, the inventor of the QF media technology (Patent pending - IT) and his son Giorgio, technical manager responsible of the R&D activity. Thanks to these Rollwasch moved forward the first formulations, recipes and special execution of several components of the Injection Moulding machines, to resist to the wearing action determined by the use of strong abrasives.

Laura De Capitani/Editor:

In 2012, Rollwasch made a big step forward with several technologies, what about?

Mr. Paolo Redaelli, C.E.O. of Rollwasch Italiana S.p.a.

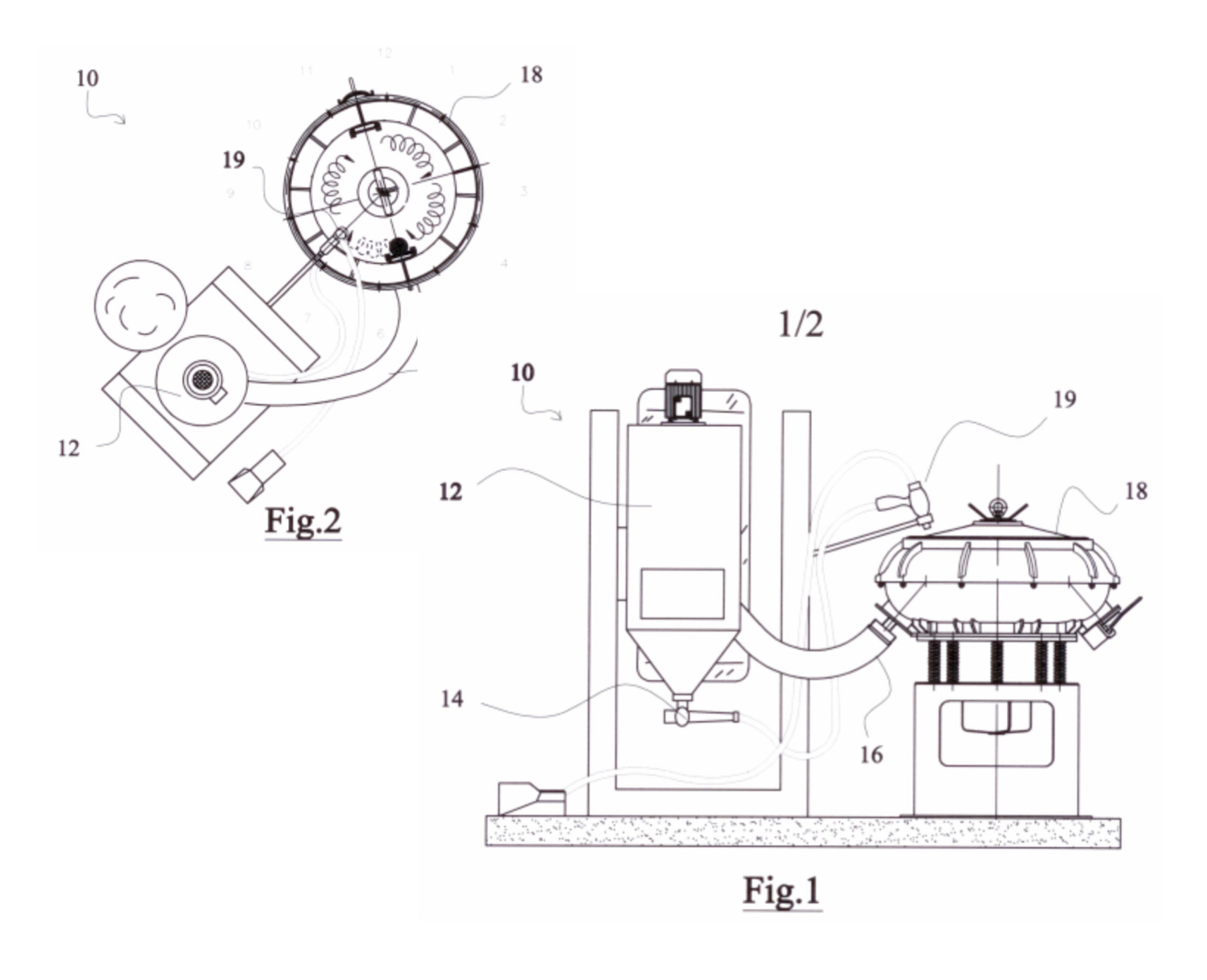

In the Headquarter of Rollwasch Italiana Spa, the inventor of the VibroBLAST technology, Paolo Redaelli, is following the patent demand of the FBMF (Fluid Bed Mass Finishing) technology, with the Patent Office Studio of Milan. After the demand for the patent protection of the QF finishing Media, Rollwasch has progressed also with the patent of the FBMF (Fluid Bed Mass Finishing) technology involving several kinds of dry finishing processes, including the VibroBLAST Technology. In the same period Rollwasch has involved an Italian partner Company, specialized in the production of blasting cabinets for decades, to agree the supply of the main elements. This, to assure to design at Rollwasch the first VibroBLAST PILOT UNIT with professional components for the sand blasting process of primary quality, reliability and efficiency.

Laura De Capitani/Editor:

For Rollwasch the period between 2012 and 2019 has been an intensive R&D period, which were the main topics you focused?

Mr. Paolo Redaelli, C.E.O. of Rollwasch Italiana S.p.a.

This period was dedicated to assure the best possible safety applications to the FBMF technology, in other words to the dry process and its related machines. Many trials have been dedicated to the use of metal alloys typically classified in the ATEX risk of explosion, like Al, Ti and Mg. The progress has gradually been reached, in a first trial campaign only with specifically formulated «QF» Media + Blasting Media + Aluminium components (the easiest to find on the market). Parallel Health considerations have been conducted by the elimination of any kind of abrasive based on Silica content, to avoid risks of diseases such as silicosis and asbestosis. In a second and massive test campaign further trials have been carried out with specifically formulated «QF» Media + Blasting Media + Aluminium components and + a SPECIAL INERTIZING POWDER. Called “A4” The INERTIZING POWDER “A4” has been used initially alone, then mixed in several percentages with abrasive powders or with the blasting media. Results have been marked with top results and with the very best safety benchmarks.

Laura De Capitani/Editor:

After this long period of research, in June 2019 you presented the new VibroBLAST technology during some fairs. What happened?

Mr. Paolo Redaelli, C.E.O. of Rollwasch Italiana S.p.a.

During 2019 we attended two fairs. In Lyon, France, at Eurexpo during the exhibition: 3D PRINT - the VibroBLAST technology has been presented in an exclusive world premiere. Rollwasch dedicated two international events in the year 2019 to present its novelty - the second one was in November at the FORMNEXT Fair in Frankfurt - Germany.

The VISION of the complete VibroBLAST range of machines was already clear and was including the main official forecasts (as in the above table). The inventor of the VibroBLAST Technology, Paolo Redaelli, was personally attending at both exhibitions, that have opened the doors to many interesting projects to supply this technology all over Europe.

Also the CFO of Rollwasch, Ambra Redaelli was present in Frankfurt, where an historical agreement started the IntegrAM, a specialistic network dedicated to the Additive Manufacturing. The machine shown in the exhibition was already sold to a French Specialist of surface finishing!