Centrifugal tumbling is a process used to finish metal parts (generally of small size). It involves placing the parts in a rotating barrel with suitable media. The rotation of each barrel creates centrifugal force, which causes the media to tumble and deburr or polish the parts.

Most frequently centrifugal tumbling is used to remove burrs, deburr, and polish metal parts. It is also used to create a uniform surface finish, smooth and with reduced roughness.

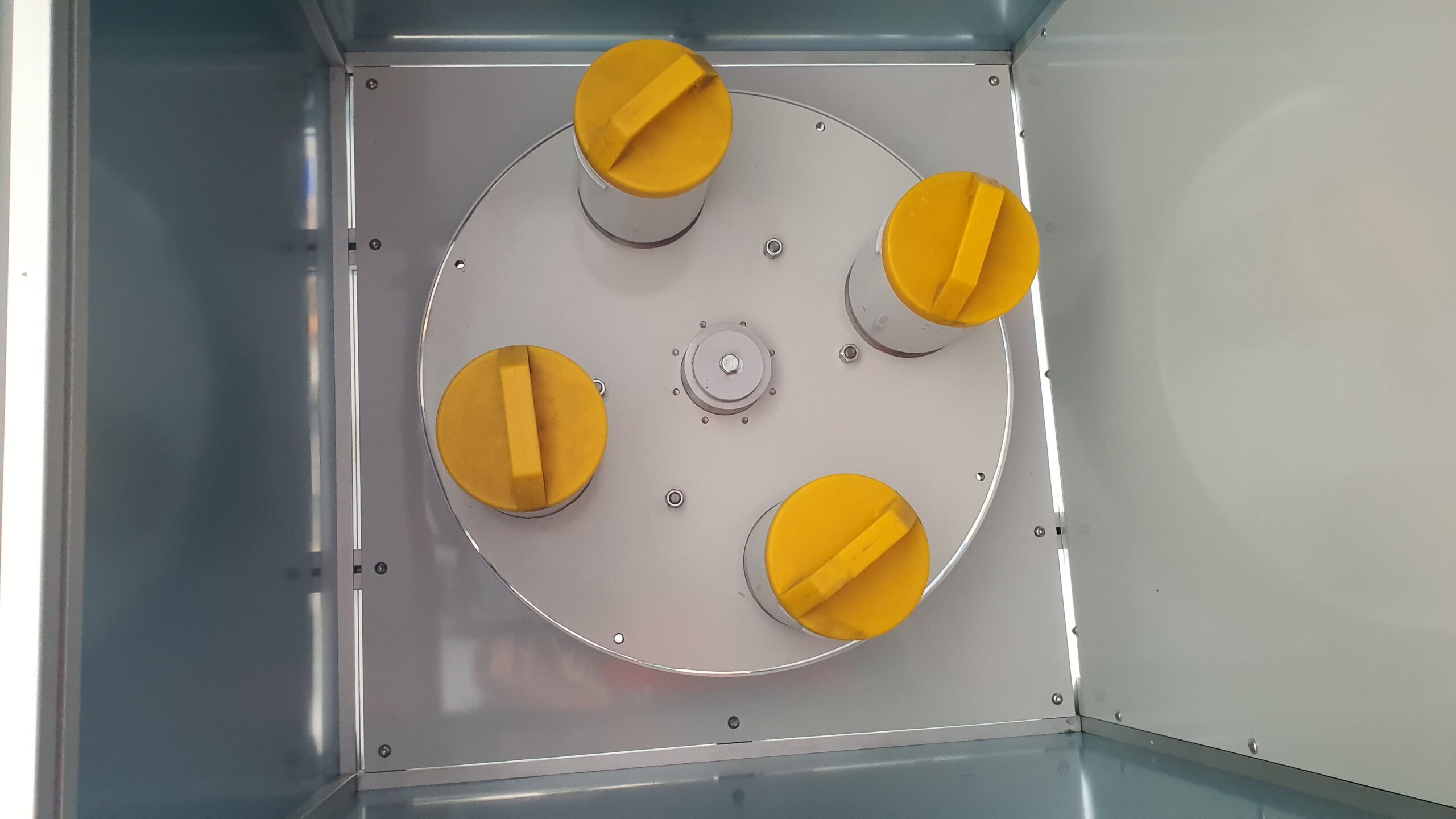

Centrifugal Tumbler Rollspin RSP-4/1 (Version 2024)

with 4 barrels of 1 liter volume each;

Rollspin RSP-4/1 (Version 2024) during a speed test;

The machines for centrifugal tumbling ar also called “Satellitic tumblers” – A satellitic tumbler is a type of barrel finishing machine that uses a combination of centrifugal force and gravity to tumble parts and media. Looking at the above picture, infact, the main rotary platform, holding the four barrels, is rotating clockwise, whilst each one of the four barrels is rotating counterclockwise. The high speed at which the finishing process are generated, does not even allow your eyes to see the barrels due to the so high speed.

The centrifugal tumblers are placed at first position in reducing the finishing time, respectively to: second – disc finishing, third – vibratory finishing, fourth – classic rotary barrel or even clock barrel.

An average proportion between the four different finishing technologies is represented as follows:

| Mass Finishing Technology | Operative Dynamics | Finishing time (Hours) |

| Rotary barrel or clock barrel | Rotation | 24 |

| Vibratory finishing (bowl) | 3D vibration | 12 |

| Disc finishing | 3D centrifugal force | 4 |

| Satellitic centrifugal tumbler | Satellitic centrifugal force | 1 |

It is a very rough and imprecise comparation, that nevertheless could give the idea of the absolute supremacy of the satellitic centrifugal barrelling technology, comparatively to any other mass finishing technology.

Considering that, between other limits, the centrifugal tumbling is generally good just for very small or small items (big parts cannot be processed), it is automatic to thik that the version with four barrels of capacity between 0,3 liters and 4 liters correspond to the best seller machines (number one the 4 barrel x 1 liter volume).

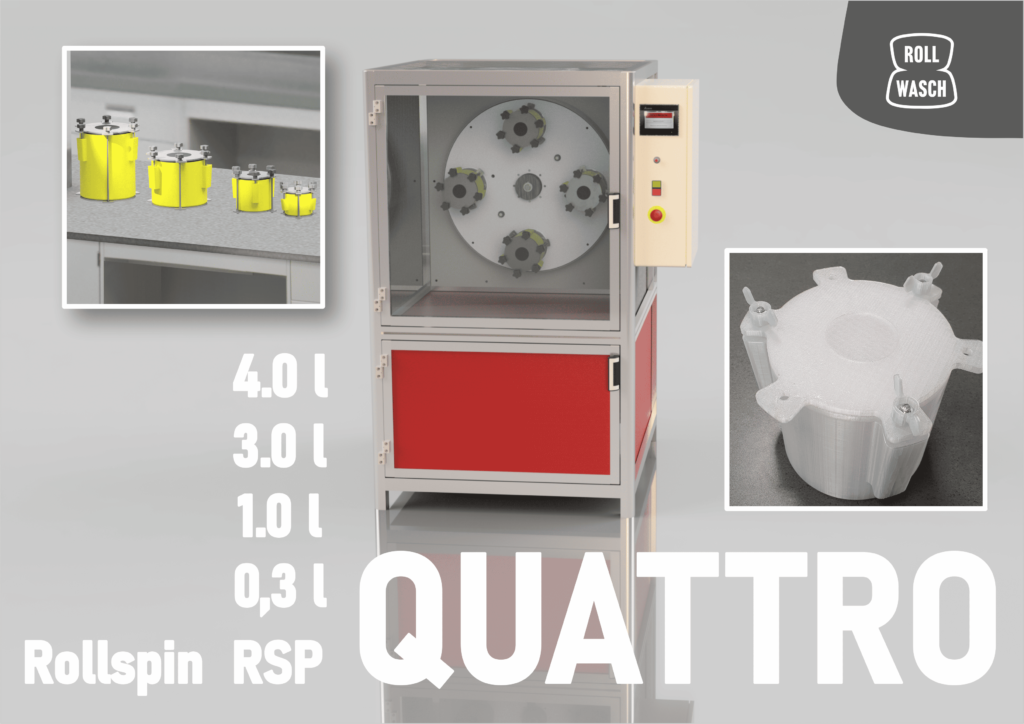

Accordingly Rollwasch started the year 2025 presenting its best seller machine, ROLLSPIN RSP-QUATTRO, offering an innovative basic unit where it is possible to configure:

4 barrels x 0,3 liter or, alternatively: 4 barrels x 1 liter or, alternatively: 4 barrels x 3 liters or, finally: 4 barrels x 4 liters.

More than flexible, each barrel can be for DRY finishing process or, alternatively, in WET version for water based finishing process!

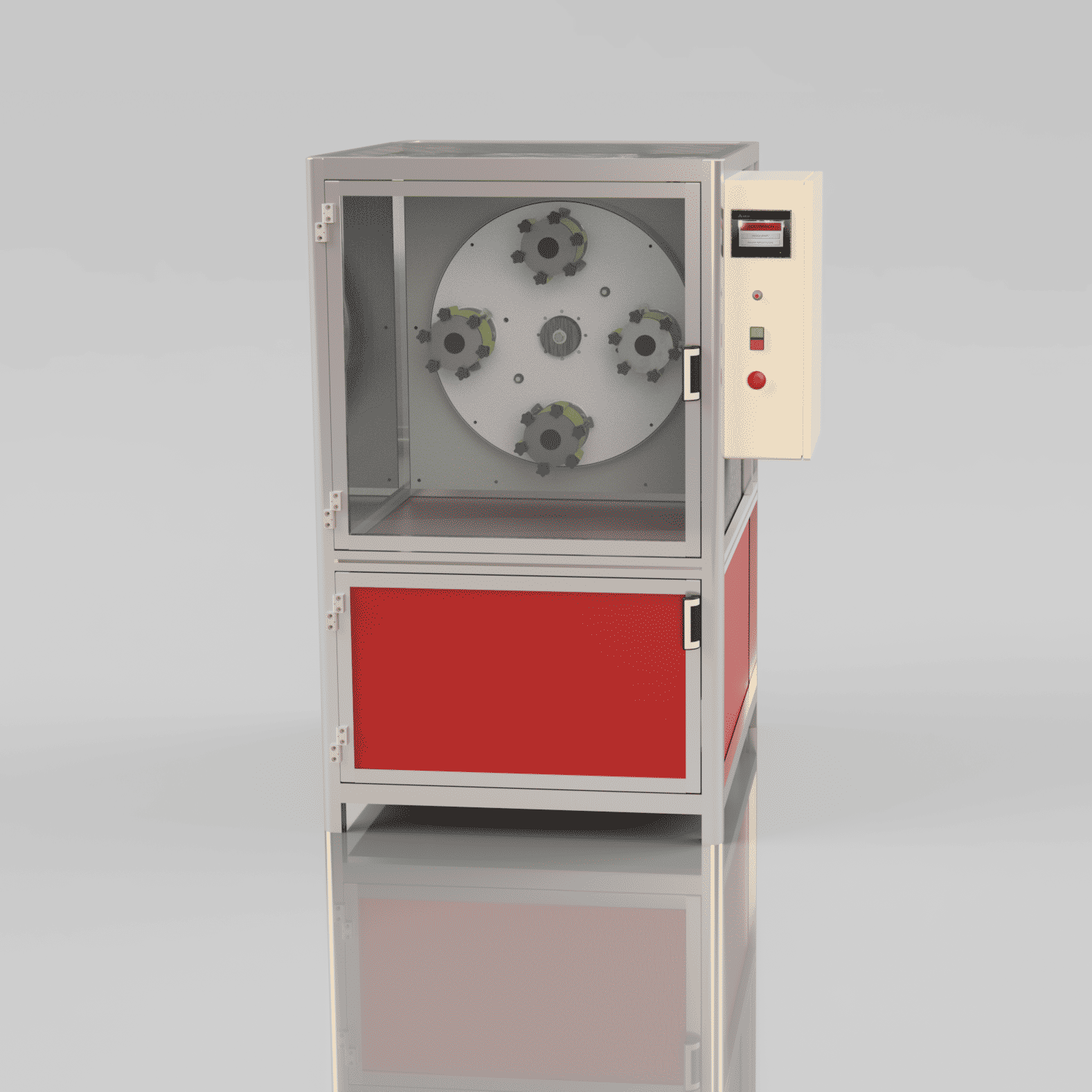

RSP-QUATTRO in configuration with 4 barrels x 1 liter, closed;

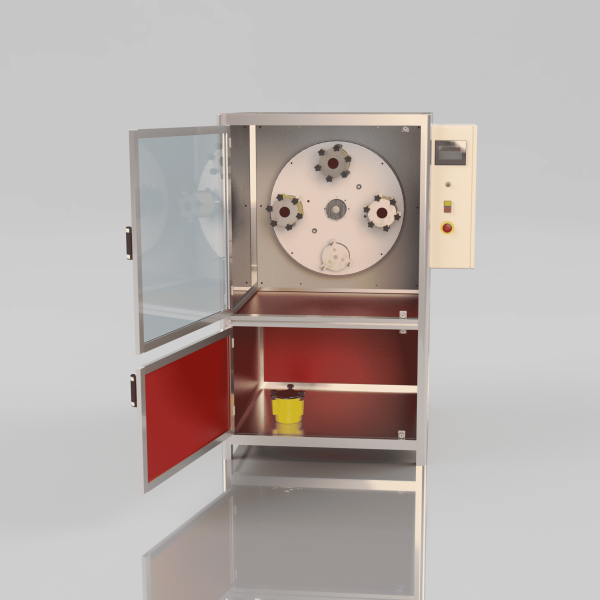

RSP-QUATTRO in configuration with 4 barrels x 1 liter, open And one barrel positioned in the storage vane;

At Rollwasch we are used to demonstrate with practical trials the results achievable with this kind of technology – the fields where this kind of machines has been most successful are, undoubtfully:

- MEDICAL (DENTAL, MAXILLO, ETC.)

- MICROMECHANICS (WATCHES, Dècolletage)

- ELECTRIC & ELECTRONICS MICRO-COMPONENTS

- ELASTOMERS, O-RING, SIMILAR PARTS

- BRAKES AND FREEZING LAMELLAR VALVES

- FASHION COMPONENTS

- JEWELLERY, LUXURY COMPONENTS

Get in touch with us for a demo trial: info@rollwasch.it

XPERT

MdM Paolo Redaelli

paolo.redaelli@rollwasch.it

CATEGORIES

Technology:

Blasting, Grinding, Media and consumables, Peening, Polishing, Post Process & Finishing for AM, PMRF, Safety, Health and Environment, Vibratory finishing

Specific category:

Vibro-blasting equipments, Vibro-Peening equipments

COMPANY

Rollwasch Italiana S.p.a.

www.Rollwasch.it