INTRODUCTION TO ECOSONIC CLEANING TECHNOLOGY

EcoSONIC is the perfect cleaning system able to perform fully AUTOMATIC CYCLES of: Washing, Rinsing and Drying.

SurfPRO-25-ECS-1, by IntegrAM

EcoSONIC is also a technology based on the 3D dynamics generated by special kinds of vectorial media loaded inside a circular vibratory finishing working bowl. Their clockwise rotation, in a spiral form, generates a suitable dynamic able to expose every turn of the bowl, the workpieces to the cavitation area (where the Ultrasonic Sonotrode is submerged in water).

EcoSONIC is a solution covered by Patent of Techno Surface – IT; this kind of system is manufactured at Rollwasch Italiana Spa, under supervision of Techno Surface and distributed towards several channels, depending on the final field of destination.

As IntegrAM the range EcoSONIC is mailnly distributed in the Additive Manufacturing field;

With other logos and license agreements, can be distributed in other specific fields.

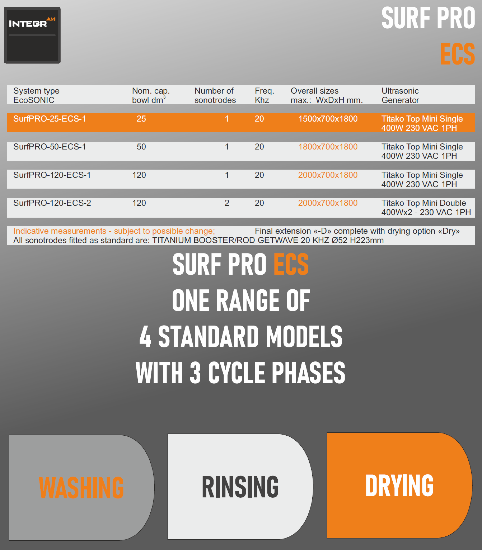

As IntegrAM, therefore, the range of systems available is presented as follows:

How can a single working bowl do three different operations in a so limited space?

Simple, the working bowl is connected to two heated tanks in stainless steel so, for example, the cycle can be as follows:

Phase1) WASHING] tank 1 loads the working bowl with washing liquid at 75°C – then vibrates at 45 HZ for 20’ minutes; at the end of this phase the water is discharged by an automatic valve on the bottom of the working bowl – a specific pneumatic device is addressing this water back to the washing tank;

Phase2) RINSING] tank 2 loads the working bowl with rinsing liquid at 65°C – then vibrates at 40 HZ for 16’ minutes; at the end of this phase the water is discharged by an automatic valve on the bottom of the working bowl – a specific pneumatic device is addressing this water back to the rinsing tank;

Phase3) DRYING] a powerful heated blower starts to blow hot air inside the working bowl with temperature gradually raising up to 70°C – then vibrates at 40 HZ for 14’ minutes; at the end of this phase the parts are hot and dried, whilst the working bowl is dried out;

The operator can defin the total unload of the mass composed by media and workpieces or, alternatively, pick up the medium size parts from the top of the working bowl.

A suitable stainless steel cover is positioned over the working bowl during the whole working cycle.

KEY POINTS OF THE ECOSONIC CLEANING TECHNOLOGY

EcoSONIC is designed with the target to be as much reduced in space as possible; in the same time it is fully automatic, but with a competitive selling price that has no comparation in the context of classic cleaning systems; beside all, this machine, due to the presence of special kinds of vectorial media, can be also programmed to do something more that the “simple” cleaning.

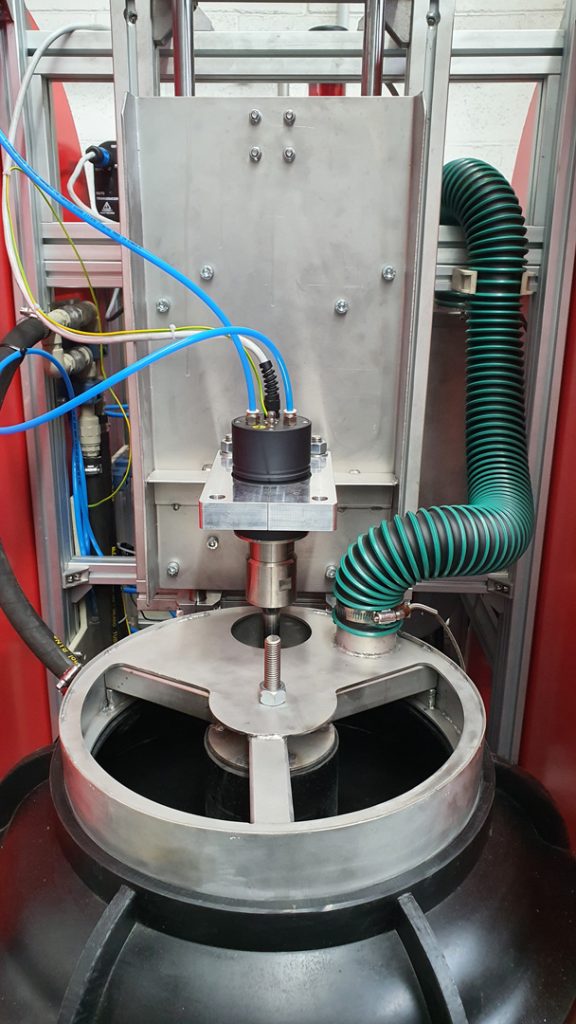

A first prothotype of EcoSONIC machine, during cleaning cycle;

Therefore, let’s resume the KEY POINTS as follows:

1. Requires very reduced space, compared with traditional washing systems;

2. With low ultrasonic frequencies can deburr blind holes with threas in high precision micromechanical components;

3. Can perform FULLY AUTOMATIC cycles, without being as much expensive as the traditional automatic systems;

A most recent pre-series machine EcoSONIC ready to work

To know more, feel free to get in touch with Techno Surface: info@technosurface.it

Or: https://technosurface.it/en/

AREA COACH

Michela Redaelli

sf4t.mktg@gmail.com

CATEGORIES

Technology:

Cleaning; Engineering & Colsunting; Post Process & Finishing for AM; Safety, Health and Environment;

Specific category:

Cleaning; Engineering & Colsunting; Post Process & Finishing for AM; Safety, Health and Environment;

COMPANY

Techno Surface Sas

www.technosurface.it