During the year 2022 at Rollwasch® the program of Centrifugal Filtering Systems RFC has been targeted for important developments and improvements.

Rollwasch® energies have been concentrated in three main directions:

- Safety Issues 2022 INTERNAL PROTOCOL UPDATE

- Optimizing basket rotational performance – BOOSTED MODE

- Expanding the family of Automatic Systems from RFC-20-A-FLOC (max. 5 kg/h) to RFC-120-A-FLOC (max. 30 kg/h)

1. Safety Issues 2022 INTERNAL PROTOCOL UPDATE

In Italy the use of this type of machine is subject to the law: art. 71 c.11 Legislative Decree 81/2008 and subsequent amendments – in other countries of EU the norms applied to centrifugal force are varying from Country to Country, for this reason a serious update of Safety Issues has been done.

The first step was to redraw the entire technical file, which was drawn up in compliance with Annex VII part A of Legislative Decree no. 17 of 27 January 2010 implementing Directive 2006/42/EC (which repeals and replaces the Directive 98/37/EC and subsequent amendments) for the purposes of affixing the CE marking to the model in question (owned by Rollwasch): RFC-20-GM-FOP Serial number: 21296

Peculiar attention has been paied to the Risk Assessment according to UNI EN ISO 12100:2010; applying the hybrid tool of UNI ISO TR 14121-2:2013 for risk estimation.

The second step was to update the USERS MANUAL, according to the following laws and norms:

Directive 2006/42/CE

Directive 2014/35/EU

Directive 2014/30/EU

Technical norms:

UNI EN ISO 12100:2010 | UNI EN 12547:2014 |

UNI EN ISO 20607:2019 | CEI EN 60204-1:2006 |

UNI EN ISO 13849-1:2016 | UNI ISO/TR 14121-2:2013 |

ROLLWASCH TECHNICAL SPECS | BOM OF THE MACHINE |

Safety is our first attention to anyone of our products, devices, machines and systems.

As far as centrifugal filtering systems are concerned, safety is a special issue to be considered during the whole life of the investment – accordingly a punctual update is required.

2. Optimizing basket rotational performance – BOOSTED MODE

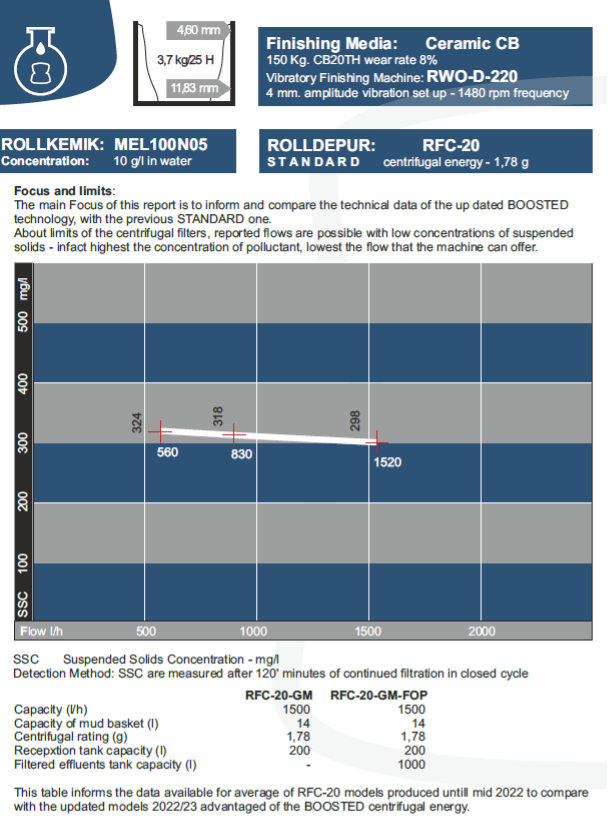

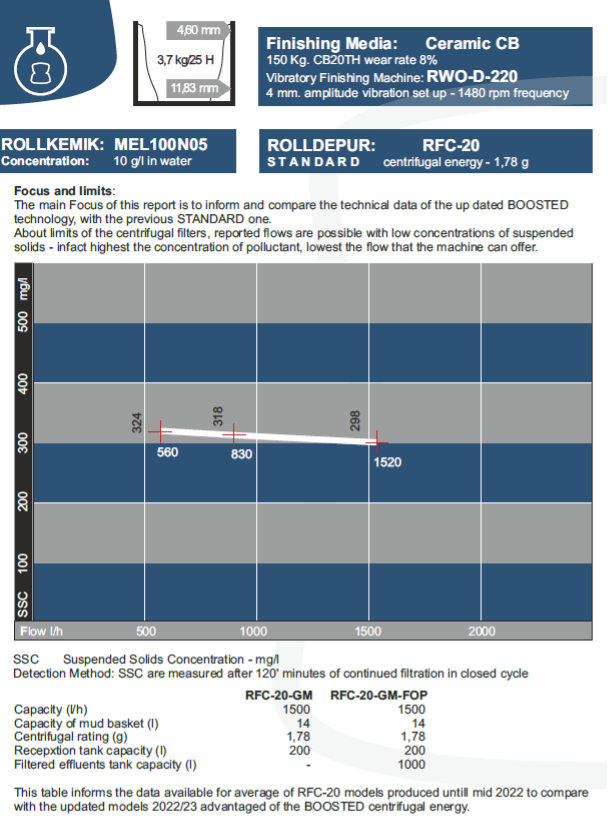

Involving one Pilot unit RFC-20-GM in its laboratories, during the year 2022 at Rollwasch®, a preliminary set of trials has been made with the most simple filtering process without flocculants.

The target of this set of trials has been to demonstrate the high efficiency of the BOOSTED MODE.

This operation MODE foresees an increased G-Force of the basket, thus to assure at same conditions, but with increased spinning-energy, improved filtration performances.

Numbers speak clearly:

Vibratory finishing unit Orbital RWO-D-220 with Ceramic Media and water

Report 2 – Ceramic media CB and BOOSTED SPEED MODE

Report 3 – Plastic media PB and STANDARD SPEED MODE

Report 4 – Plastic media PB and BOOSTED SPEED MODE

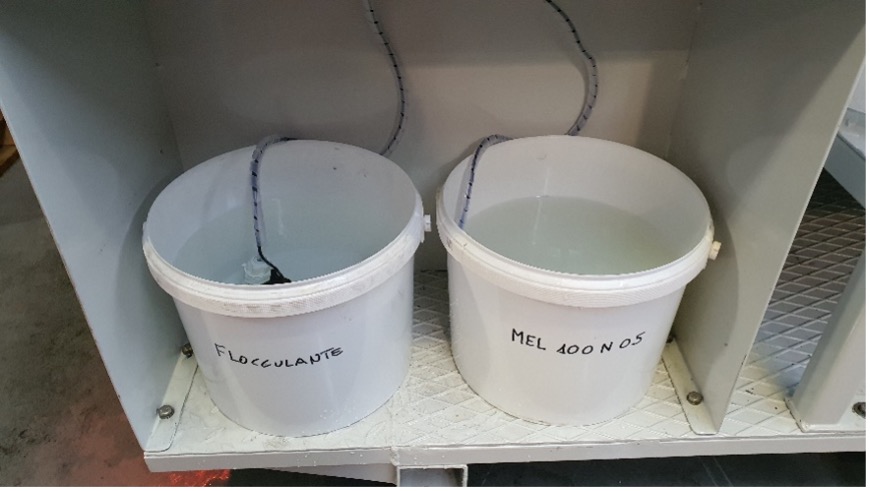

Involving one completely new Pilot unit RFC-20-A-FLOC in its laboratories, between the end of 2022 and the beginning of 2023 at Rollwasch®, a further set of trials is going to be made with the most evoluted filtering process based on liquid flocculants range ROLLKEMIK DEPUR.

Centrifugal filter RFC-20-A-FLOC – The target of this set of trials has been to demonstrate the high efficiency of the BOOSTED MODE.

This operation MODE foresees an increased G-Force of the basket, thus to assure at same conditions, but with increased spinning-energy, improved filtration performances.

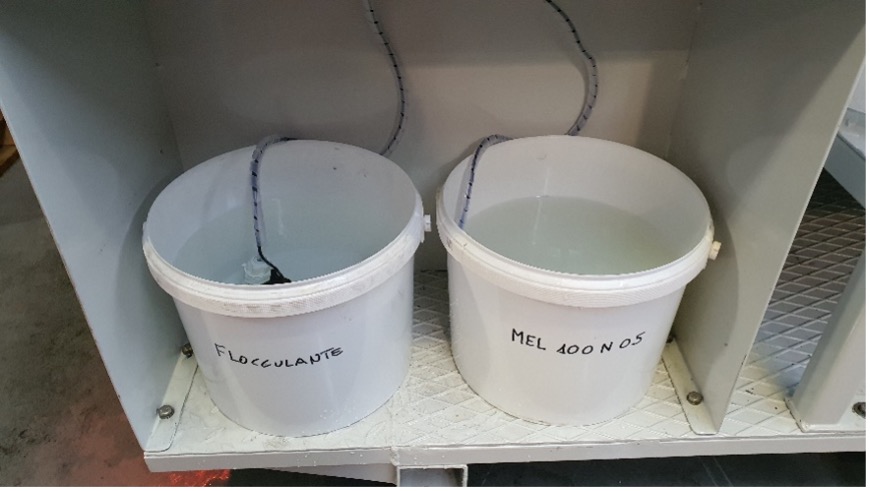

1 Automatic dosing station both for refilling of liquid levels and for keeping the finishing compound concentration at a certain value – a second pump provides the automatic dosage of flocculant;

2 Electric control board separated by the hydraulic/pneumatic board and from the dispenser area where chemical compounds are automatically pumped

3 Mud thickenig (white mud) on the wall of the basket

4 Buffer tank for filtered wastewater, complete with level sensors and pre-decanter for efficient periodic cleaning operations

5 a screen page of the programming software of the various filtration phases alternating with the automatic cleaning of the basket (sludge removal)

6 automatic orientation of the discharge from the centrifuge towards the tank with filter bag or towards the relaunch tank

7 the recovery tank also receives the leachate from the tank with filter bag, where the sludge is collected and finally destined for pre-disposal storage

3. Expanding the family of Automatic Systems from RFC-20-A-FLOC (max. 5 kg/h) to RFC-120-A-FLOC (max. 30 kg/h)

During the year 2023 Rollwasch® will work heavily on the project to expand the family of the Automatic Centrifugal Filtering by adding to the milestone of the RFC-20-A-FLOC version (supposed to be efficient up to the limit of max. 5 kg/h of mud) and to the twin filter model RFC-20-A-FLOC.MK-P1-E5-K2 (up to max. 10 kg/h of mud) the new model RFC-120-A-FLOC, to perform filtering up to 30 kg/h of mud, in the single version, then to upgrade with multiple versions to 60, 90, 120 and more kg/h of mud.

The concept to combine multiple filters in case of high volumes to be processed, is part of the new generation filtering systems.

To know more stay connected to SF4T in the next months!

XPERT

MdM Paolo Redaelli

paolo.redaelli@rollwasch.it

CATEGORIES

Technology:

Blasting, Grinding, Media and consumables, Peening, Polishing, Post Process & Finishing for AM, PMRF, Safety, Health and Environment, Vibratory finishing

Specific category:

Vibro-blasting equipments, Vibro-Peening equipments

COMPANY

Rollwasch Italiana S.p.a.

www.rollwasch.com