During the year 2022 IntegrAM has developped a new range of COATING SYSTEMS based on an innovative technology covered by Patent demand.

LubroCOAT process is based on top efficiency of the application of any kind of coating substance over a polymer or elastomer (such as O-RING and similar components). This happens in quite a few steps, like:

- Pre-Heating of the components during their rotational movement inside the working bowl or processing chamber – this can be done with hot air, or DSS (Dry Saturated Steam) or a combination of both of them;

- Coating by spraying the liquid or gel coating chemical compound itself, or combined with DSS which is generating a sort of opening of the surface, making it more receptive to the coating substance;

- Final Drying of the components during their rotational movement inside the working bowl or processing chamber – this can be done with hot air, or DSS (Dry Saturated Steam) or a combination of both of them;

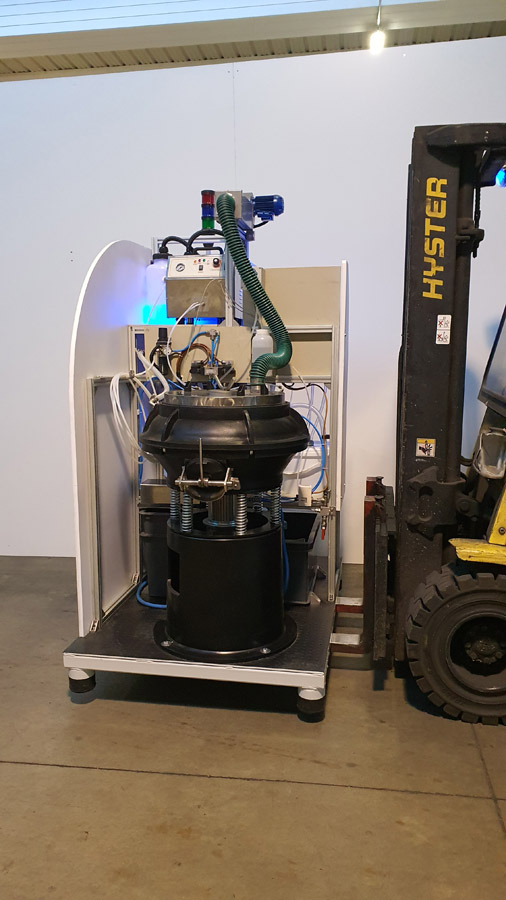

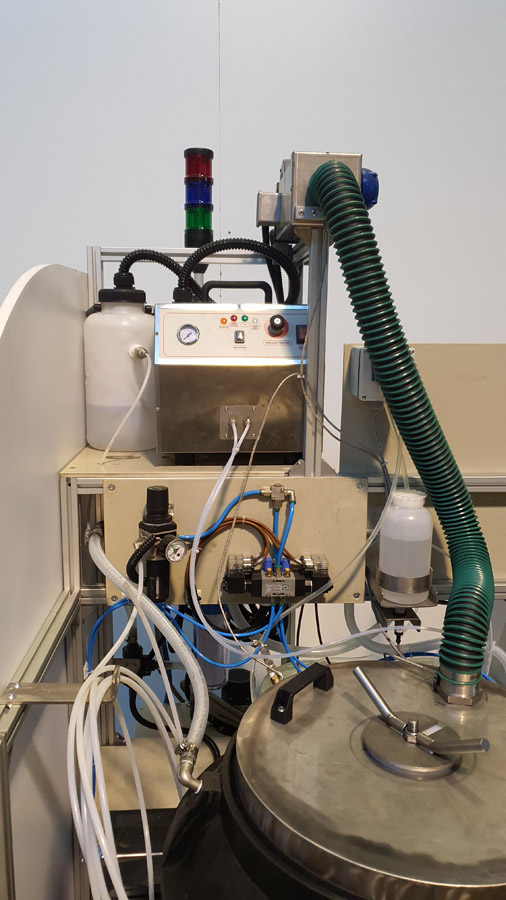

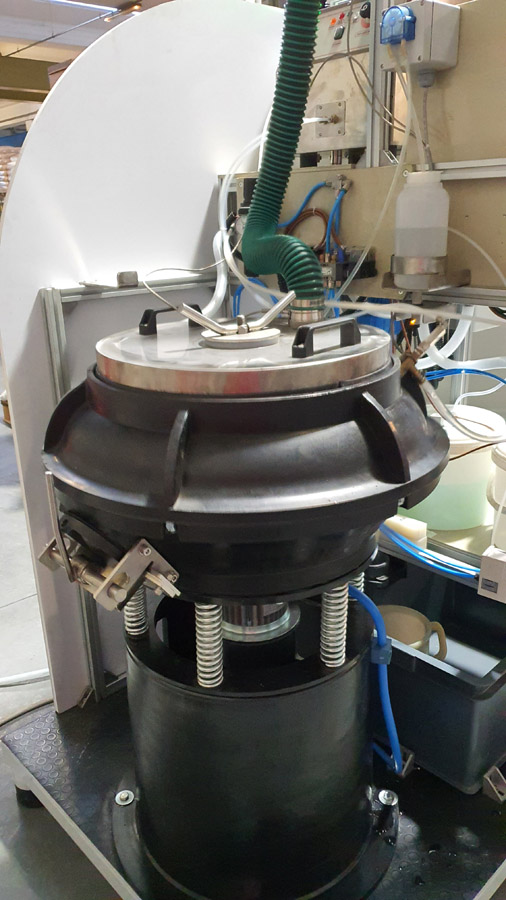

The range of machines dedicated to this innovative LubroCOAT process is the SurfPRO line of circular bowl vibrators.

The SURF-PRO series of PROFESSIONAL surface finishing machines is therefore available in the LubroCOAT version – this too on easily positionable technological pallets and with the prerogative of being PLUG & PLAY.

The LubroCOAT line allows you to carry out mass lubrication processes of elastomers, polymers, composites of various kinds.

Thanks to the LubroCOAT line it is also possible to carry out treatments such as:

- TOP-COAT;

- BIO-COAT;

- NANO/FUNCTIONAL COATING;

Let’s see in detail the skills of this innovative process technology:

- TOP COAT – That is, applying a lubricating layer to the surface, or coating the surface with a lubricating substance (typical example: Teflon).

- BIO COAT – That is, applying a layer of bio-compatible substances to the surface, or coating the surface with natural substances, such as beeswax for example.

- NANO/FUNCTIONAL COATING – That is, applying a protective layer or a functional layer to the surfaces involved, with high degrees of efficiency.

Some Nano-Additives allow to achieve important properties. In fact, just as an example, the surface properties of organic polymer coatings can be improved with some nano-additives, to be more hydrophobic, oil repellent and scratch resistant.

The additives or Nano-Additives contain nanoparticles created by the hydrolysis and condensation of silanes (sol-gel technology).

The combination of different silanes, which are synthesized in a special process, results in organically modified silica sols with about 30% solids and long shelf life.

Example of LubroCOAT phase, using the DSS injection combined with the suitable percentage of coating substance.

SurfPRO range of LubroCOAT systems is available in standard configuration starting from 25, to 50 up to 120 liters of nominal capacity.

All machines are available with HMI designed with a touch screen colour display combined with software to manage recipes of different kinds, tailor made for each customer.

For further information : tech@integram.eu

XPERT

Spencer Williams

integram.team@gmail.com

CATEGORIES

Technology:

Post Process & Finishing for AM, Dyeing, Powder recovery & selection, Surface Finishing, Unpacking or Decaking, Coating

Specific category:

Post Process & Finishing for AM; Scientific Head of R&D; Webinars & Seminars; Circular Economy Technology;

COMPANY

IntegrAM

www.integram.eu