ECO-SONIC FINISHING

Innovative ultrasonics technology to offer environmental eco-sustainability to various surface treatment processes.

Techno SURFACE is proud to create technologically innovative systems based on ultrasonic cavitation, through which it is possible to process components efficiently and cleanly.

The machines and systems for surface treatment designed by Techno SURFACE are oriented to solve in an eco-sustainable and innovative way processes such as the ultrasonic deburring eco-sonic of the surfaces of metal articles and other materials such as polymers, ceramics, composites, glass, with important advantages for the end user.

Some solutions designed by Techno SURFACE are also the subject of a patent pending demand.

Clean energy

Techno Surface collaborates with ultrasonic manufacturers and leading manufacturers of finishing machines internationally, for the development of exclusive and innovative solutions.

Some information on Ultrasonic technology:

As for the drooling action of ultrasounds or the ultrasonic cavitation of liquids, it should be remembered that ultrasonic waves of high intensity ultrasound generate cavitation in liquids. Cavitation causes extreme effects locally, such as jets of liquids up to 1000 km / h, pressures up to 2000 atm and temperatures up to 5000 Kelvin. Ultrasonic waves of high intensity ultrasound generate cavitation in liquids. In the case of high intensity sound liquids, the sound waves that propagate in the liquid translate into alternating cycles of high (compression) and low pressure (rarefaction), with frequencies varying according to the frequency. During the low pressure cycle, high intensity ultrasonic waves create small vacuum or void bubbles in the liquid. When the bubbles reach a volume at which they can no longer absorb energy, they collapse violently during a high pressure cycle. This phenomenon is called cavitation. During the implosion temperatures (approx. 5.000K) and pressures (approx. 2.000atm) are very high. The implosion of the cavitation bubble also produces jets of liquid up to 280m / s of speed.

Sources:

Literature Suslick, K.S. (1998): Kirk-Othmer Encyclopedia of chemical technology; 4th

Ed. J. Wiley & Sons: New York, 1998, vol. 26, 517-541.

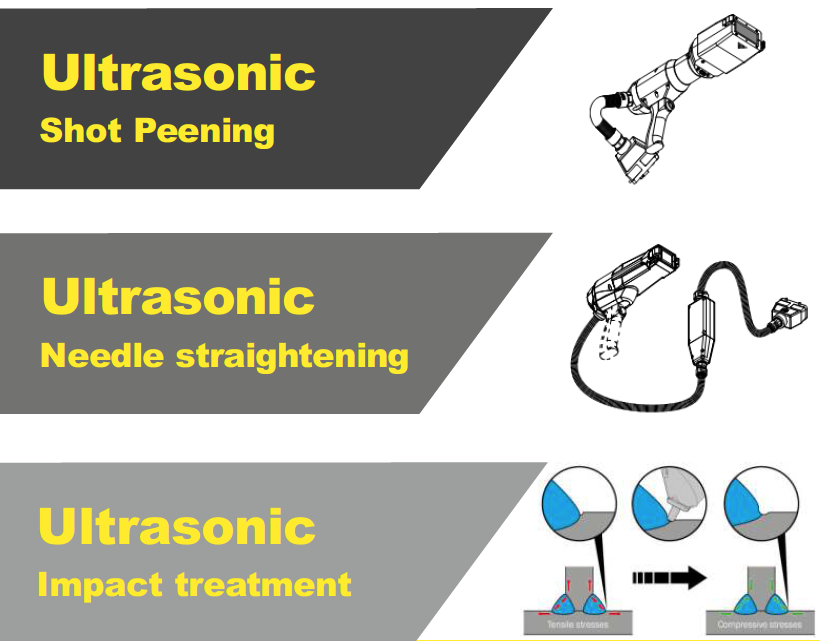

Innovative technology for inducement of compressive stresses, improvement of the fatigue resistance, based on ultrasonics.

Techno SURFACE collaborates with international partners specialized in the use of ultrasonics for applications aimed at surface treatment with applications for the improvement of resistance to the fatigue of welding, applicable with transportable systems to structures such as metal bridges and related metal constructions.

As well as innovative ultrasonic technologies, they are extremely respectful of the environment and have a lower carbon footprint than traditional systems. Particularly interesting are the applications of ultrasonic shot peening, for Automotive, Aerospace, energy, medical and Additive Manufacturing components.

Ultrasonic Shot Peening

How does USP ultrasonic shot peening work for the automotive industry?

Unlike conventional shot blasting that uses compressed air or rotating turbines, the USP (Ultrasonic Shot Peening) uses – dry – ultrasonic vibrations with a frequency of 20KHz and with variation in the shot blasting width of the media on the surface of the piece.

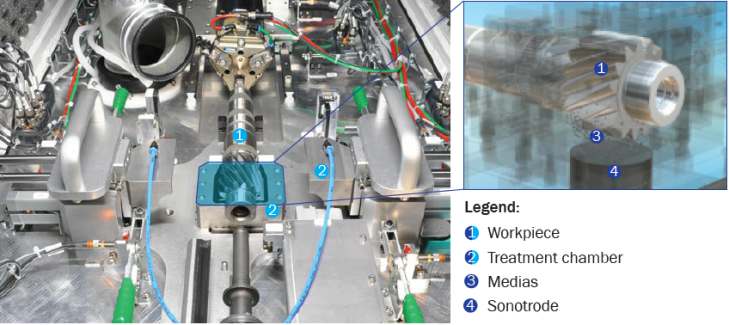

The example on this page reproduces a customized USP machine for the treatment of drive shafts and a 3D view during the ultrasonic shot blasting process.

Why use ultrasonic shot blasting?

USP ultrasonic shot peening is a surface enhancement of metal components that positively influences their resistance to fatigue and corrosion, significantly increasing their durability, in addition:

It prevents cracks from starting and growing

Prevents breakage from corrosion stress

Wear reduction phenomena

Extension of component life

Techno Surface represents technological partners with equipped laboratories able to offer feedback based on the most varied criteria, or standards – in general we prefer to carry out demonstration tests which, often, leave no doubt about the superiority and convenience of the technologies used – let’s talk!

We have interesting comparisons, presentations and information, let’s get to know each other and talk about it when you want!

AREA COACH

Michela Redaelli

sf4t.mktg@gmail.com

CATEGORIES

Technology:

Cleaning; Engineering & Colsunting; Post Process & Finishing for AM; Safety, Health and Environment;

Specific category:

Cleaning; Engineering & Colsunting; Post Process & Finishing for AM; Safety, Health and Environment;

COMPANY

Techno Surface Sas

www.technosurface.it