Thermal deburring of metal components

Thermal deburring is aimed at removing burrs on components in oxidizable materials with PATENTED TECHNOLOGY AT HORIZONTAL CHAMBER

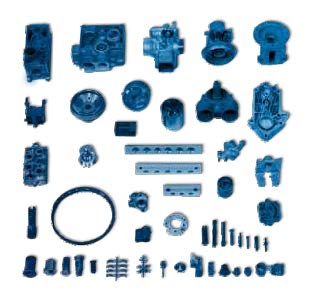

Explore with Techno SURFACE the opportunities offered by thermal deburring processes. Thermal deburring is a process aimed at eliminating burrs on components in oxidizable materials that come from specific processes (mechanical, die-castings, etc.).

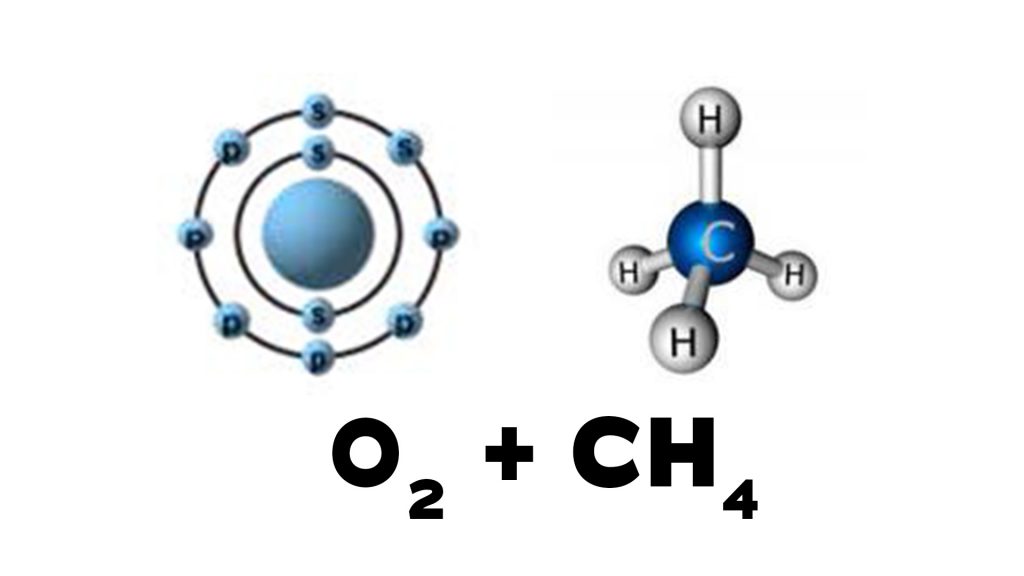

The process uses, according to a chemical-physical principle, the heat generated by the ignition of a suitable combustible mixture, just like in the case of thermal engines, in an horizontal chamber (patent pending – I).

The energy obtained uses the oxygen present in the ordinary mixture to eliminate burrs, slag and unwanted material present on the edges, within the cavities and on the more or less hidden surfaces of the details subjected to the treatment.

Any threaded parts present on the parts to be treated are not affected by the process thanks to the geometry of the thread itself.

At the end of the treatment, the pieces have an oxide patina deposited on the surfaces.

NEGOTIABLE MATERIALS

- Metal parts that are oxidizable and obtained by casting or mechanical processing.

- Details in cast iron, steel, copper and its alloys, aluminum and its leche, still not heat treated and free of oils or fats.

Machinery and horizontal chamber technology are innovative, protected by patents and bringing important benefits in terms of production efficiency and lower costs.

AREA COACH

Michela Redaelli

sf4t.mktg@gmail.com

CATEGORIES

Technology:

Cleaning; Engineering & Colsunting; Post Process & Finishing for AM; Safety, Health and Environment;

Specific category:

Cleaning; Engineering & Colsunting; Post Process & Finishing for AM; Safety, Health and Environment;

COMPANY

Techno Surface Sas

www.technosurface.it